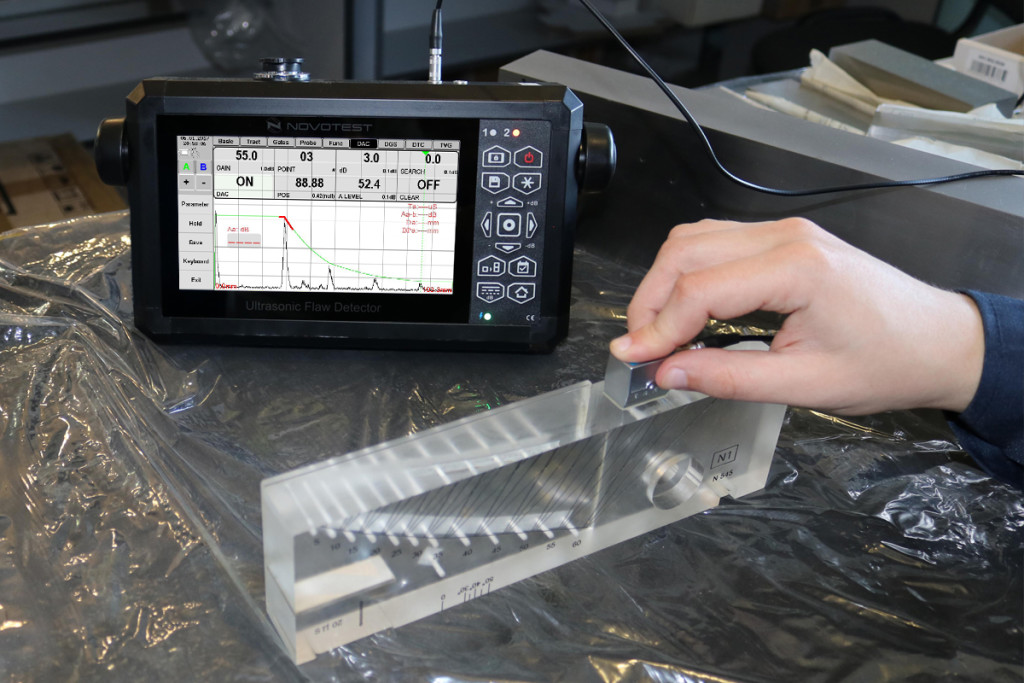

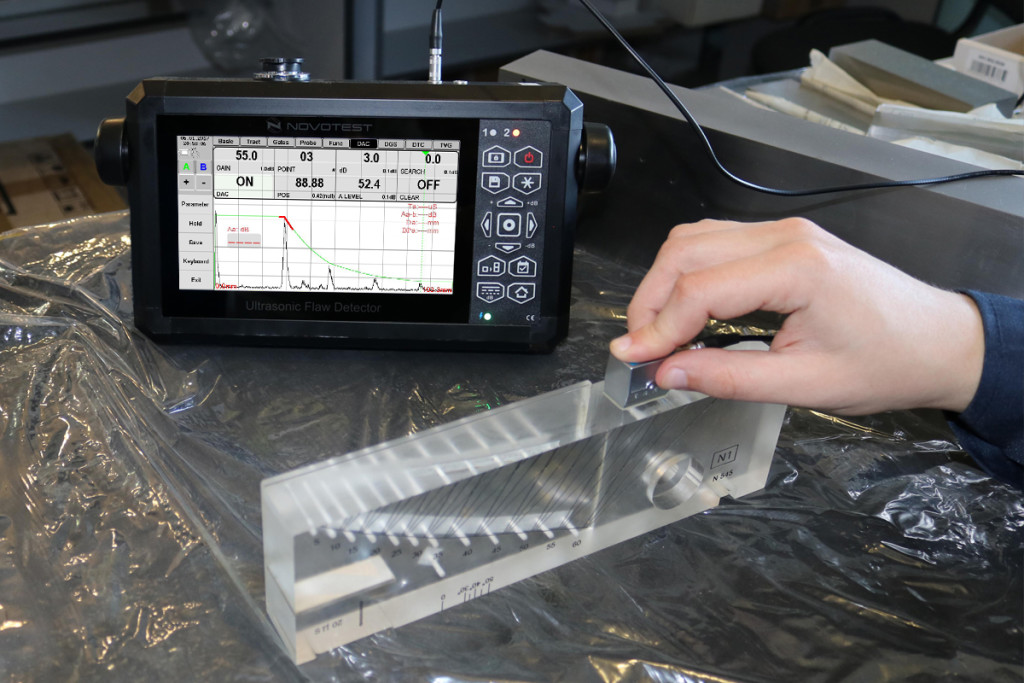

Ultrasonic Flaw Detector NOVOTEST UD3701

The Ultrasonic Flaw Detector NOVOTEST UD3701 is designed to detect internal defects, such as discontinuities and heterogeneities of materials in products and welds, determine coordinates and evaluate defect parameters, measure thickness and the velocity of propagation and attenuation of ultrasonic waves in the materials (metals, plastics, glass and etc.), the search for places of corrosion, cracks, internal delamination and other defects.

Ultrasonic Flaw Detector NOVOTEST UD3701 is a universal, powerful, functional, ergonomic and reliable device for solving tasks of ultrasonic flaw detection both in the laboratory and in the field.

BRIGHT TFT TOUCHSCREEN DISPLAY

Thanks to the multi-touch screen, the operator can easily move the gates and set the scan without using buttons and encoders. All functions for setting up and controlling the device can be carried out both through the touchscreen and in the classic way – using the keyboard. The TFT display of the device is very bright and contrasting with a resolution of 800×480 pixels, which allows users to get clear picture of the signals on the screen.

AVAILABILITY OF MANY USEFULL FUNCTIONS

The envelope mode of the signal allows user to detect the maximum of signals, as well as get the envelope of the signal curve when scanning the reflector.

Auto zoom – the electronic magnifier mode allows operator to focus the scan on the selected gate by clicking just one key.

Fill function – designed to improve the perception of the image on the screen of the device. The A-Scan signal is filled with the color matching the color of the signal line.

Simulation of a measurement from a stored record in the instrument memory.

The presence of movable blocks of output of measured values, which allows the operator to arrange blocks of parameters at any place of the A-scan.

DAC & TVG

The Ultrasonic Flaw Detector NOVOTEST UD3701 has the ability to build and configure the Distance Amplitude Correction (DAC) and Time Varied Gain (TVG) functions, using up to 16 points, to estimate the size of the reflectors relative to the reference ones at different depths.

DGS CURVES

Using the DGS (Distance Gain Size) mode, the operator can configure the device according to the signal from the reference reflector, and then receive automatic calculation of equivalent reflector sizes at various depths.

Ultrasonic Flaw Detector NOVOTEST UD3701

The Ultrasonic Flaw Detector NOVOTEST UD3701 is designed to detect internal defects, such as discontinuities and heterogeneities of materials in products and welds, determine coordinates and evaluate defect parameters, measure thickness and the velocity of propagation and attenuation of ultrasonic waves in the materials (metals, plastics, glass and etc.), the search for places of corrosion, cracks, internal delamination and other defects.

Ultrasonic Flaw Detector NOVOTEST UD3701 is a universal, powerful, functional, ergonomic and reliable device for solving tasks of ultrasonic flaw detection both in the laboratory and in the field.

BRIGHT TFT TOUCHSCREEN DISPLAY

Thanks to the multi-touch screen, the operator can easily move the gates and set the scan without using buttons and encoders. All functions for setting up and controlling the device can be carried out both through the touchscreen and in the classic way – using the keyboard. The TFT display of the device is very bright and contrasting with a resolution of 800×480 pixels, which allows users to get clear picture of the signals on the screen.

AVAILABILITY OF MANY USEFULL FUNCTIONS

The envelope mode of the signal allows user to detect the maximum of signals, as well as get the envelope of the signal curve when scanning the reflector.

Auto zoom – the electronic magnifier mode allows operator to focus the scan on the selected gate by clicking just one key.

Fill function – designed to improve the perception of the image on the screen of the device. The A-Scan signal is filled with the color matching the color of the signal line.

Simulation of a measurement from a stored record in the instrument memory.

The presence of movable blocks of output of measured values, which allows the operator to arrange blocks of parameters at any place of the A-scan.

DAC & TVG

The Ultrasonic Flaw Detector NOVOTEST UD3701 has the ability to build and configure the Distance Amplitude Correction (DAC) and Time Varied Gain (TVG) functions, using up to 16 points, to estimate the size of the reflectors relative to the reference ones at different depths.

DGS CURVES

Using the DGS (Distance Gain Size) mode, the operator can configure the device according to the signal from the reference reflector, and then receive automatic calculation of equivalent reflector sizes at various depths.

YOU MAY ALSO LIKE