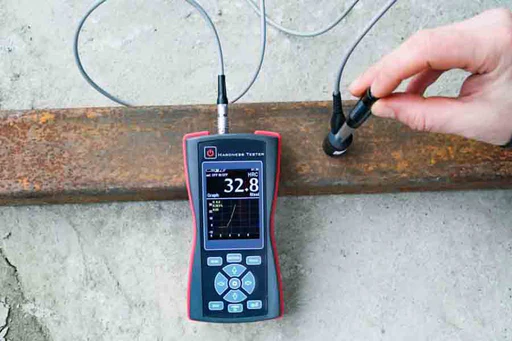

QH5 U Portable UCI Hardness Tester for metals

The QH5 Series Portable Leeb Metal Hardness Testers are advanced, reliable tools designed for fast and precise hardness measurements on various metal parts, including complex shapes and massive components. Utilizing the Leeb rebound method, the QH5 series offers flexibility across different hardness units such as Rockwell, Brinell, Vickers, Shore, and MPa. With compatibility for multiple impact devices, it delivers unparalleled versatility for confined spaces, rough surfaces, and specialized material testing. Built with a lightweight design, high-capacity memory, USB connectivity, and advanced CalTag technology, this tester is the perfect choice for production, material classification, and quality control in industrial environments.

Features

- Leeb Rebound Testing: Fast and accurate hardness measurements across a wide range of materials.

- CalTag Technology: Automatic calibration for impact devices ensures consistent accuracy.

- Versatile Impact Devices: Compatible with six types of impact devices (D, DC, C, G, DL, E) for various applications.

- Wide Material Compatibility: Measures hardness in steel, stainless steel, aluminum, cast iron, brass, copper, and bronze.

- Multiple Hardness Units: Measures in Rockwell (B/C), Brinell, Vickers, Shore, Leeb, MPa, and user-defined units.

- High Memory Capacity: Stores up to 32,000 readings for efficient data management.

- Data Connectivity: USB interface for transferring data to PCs.

- Portable Design: Lightweight (182 g) and compact for easy handling.

- Durable Build: IP-rated housing with robust construction for industrial use.

- Advanced Reporting: Includes dmq DataCenter software for data analysis and reporting.

| Hardness Measurement Range | HV 100 – 950

|

| Accuracy | ±5% across the entire HV range

|

| Compatible Probes | |

| 10N | Polished surfaces and small parts

|

| 50N | Treated parts, crankshafts, and HAZ in welds

|

| 98N | Rough surfaces, weld seams, and large parts

|

| Memory | 32,000 readings

|

| Power Supply | 2 x AA batteries

|

| Battery Life | 150 hours (with backlight off)

|

| Dimensions | 79 x 117 x 32 mm

|

| Weight | 182g (0.40 lbs)

|

| Standards | ASTM A1038, ASTM E140, CE marking

|

QH5 U Portable UCI Hardness Tester for metals

The QH5 Series Portable Leeb Metal Hardness Testers are advanced, reliable tools designed for fast and precise hardness measurements on various metal parts, including complex shapes and massive components. Utilizing the Leeb rebound method, the QH5 series offers flexibility across different hardness units such as Rockwell, Brinell, Vickers, Shore, and MPa. With compatibility for multiple impact devices, it delivers unparalleled versatility for confined spaces, rough surfaces, and specialized material testing. Built with a lightweight design, high-capacity memory, USB connectivity, and advanced CalTag technology, this tester is the perfect choice for production, material classification, and quality control in industrial environments.

Features

- Leeb Rebound Testing: Fast and accurate hardness measurements across a wide range of materials.

- CalTag Technology: Automatic calibration for impact devices ensures consistent accuracy.

- Versatile Impact Devices: Compatible with six types of impact devices (D, DC, C, G, DL, E) for various applications.

- Wide Material Compatibility: Measures hardness in steel, stainless steel, aluminum, cast iron, brass, copper, and bronze.

- Multiple Hardness Units: Measures in Rockwell (B/C), Brinell, Vickers, Shore, Leeb, MPa, and user-defined units.

- High Memory Capacity: Stores up to 32,000 readings for efficient data management.

- Data Connectivity: USB interface for transferring data to PCs.

- Portable Design: Lightweight (182 g) and compact for easy handling.

- Durable Build: IP-rated housing with robust construction for industrial use.

- Advanced Reporting: Includes dmq DataCenter software for data analysis and reporting.

| Hardness Measurement Range | HV 100 – 950

|

| Accuracy | ±5% across the entire HV range

|

| Compatible Probes | |

| 10N | Polished surfaces and small parts

|

| 50N | Treated parts, crankshafts, and HAZ in welds

|

| 98N | Rough surfaces, weld seams, and large parts

|

| Memory | 32,000 readings

|

| Power Supply | 2 x AA batteries

|

| Battery Life | 150 hours (with backlight off)

|

| Dimensions | 79 x 117 x 32 mm

|

| Weight | 182g (0.40 lbs)

|

| Standards | ASTM A1038, ASTM E140, CE marking

|

YOU MAY ALSO LIKE